HALE UAV Technology

Maximum 48 Hours Endurance

Potentially Unlimited Endurance

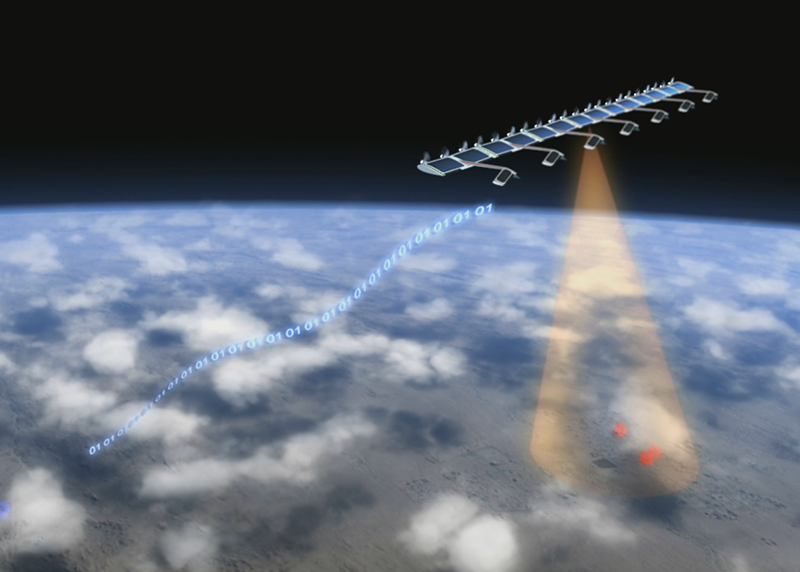

Cognitive UAV Mission Requirements

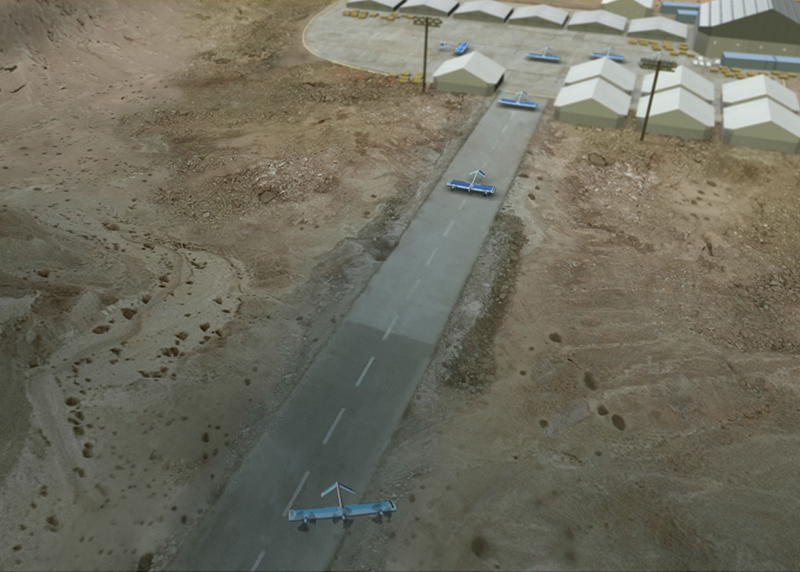

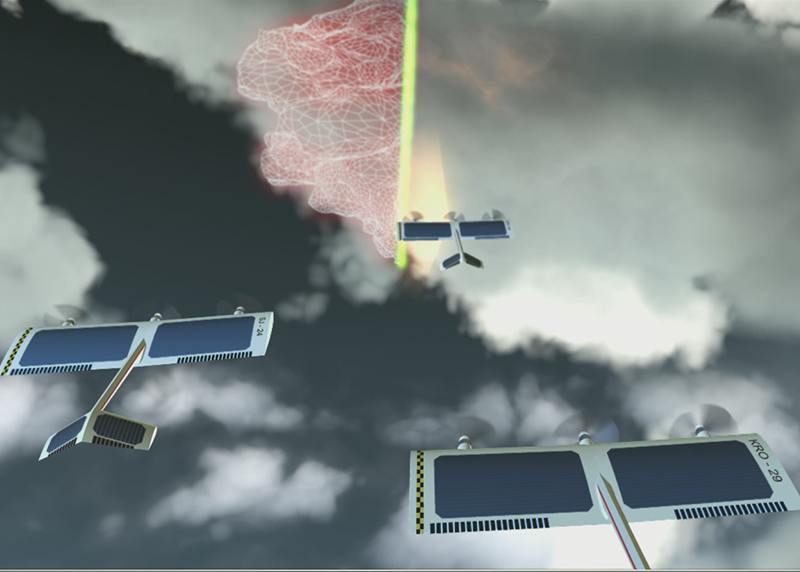

- Rapidly deployable, highly survivable ISR platform

- Ability to take-off from small general aviation runways (4000ft x 75ft)

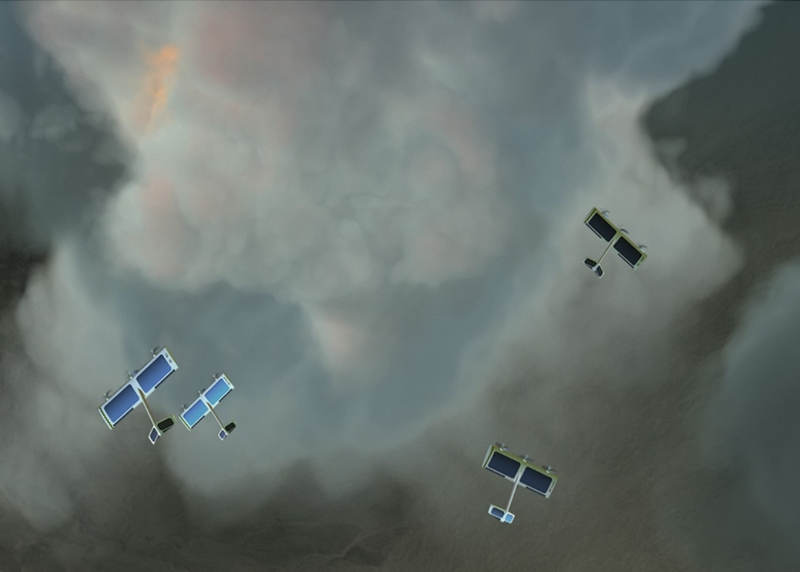

- Loiter at 60,000 ft for 15 days with 99% probability of station keeping

- Payload is assumed to be 250 lbs and the power consumption is 1.5 kW – distributed among the cellular aircraft

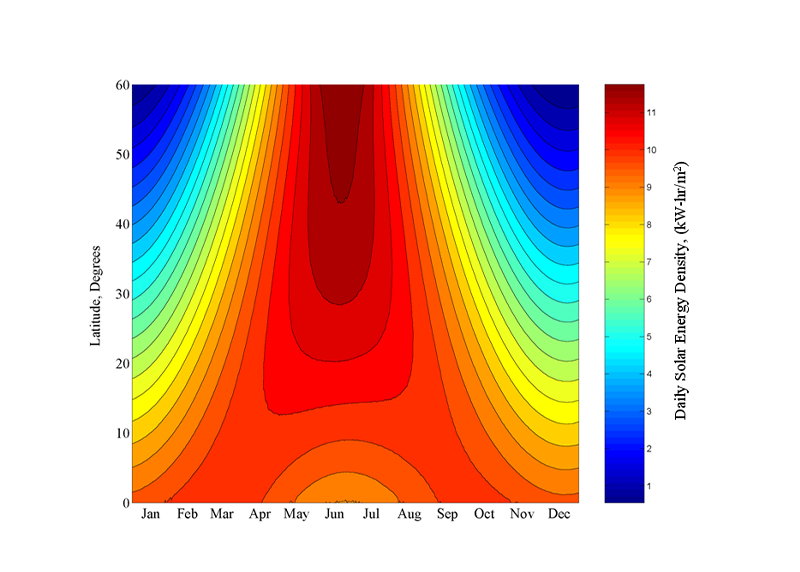

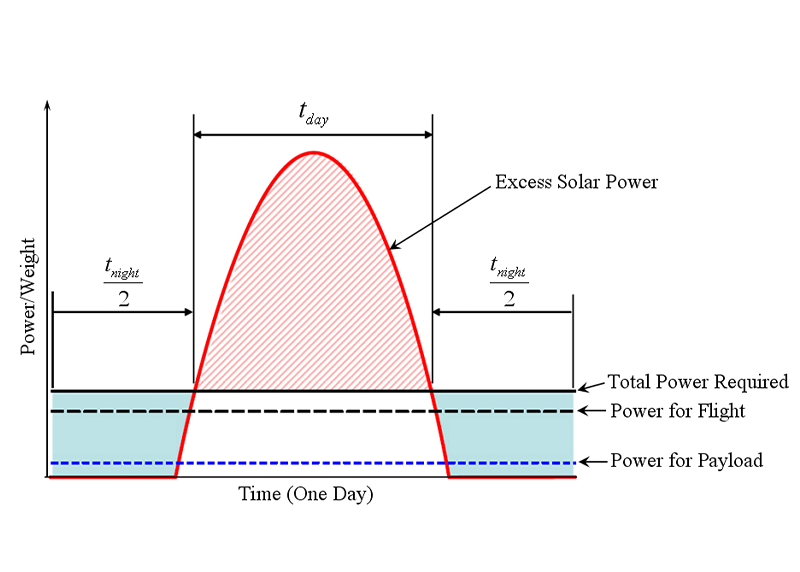

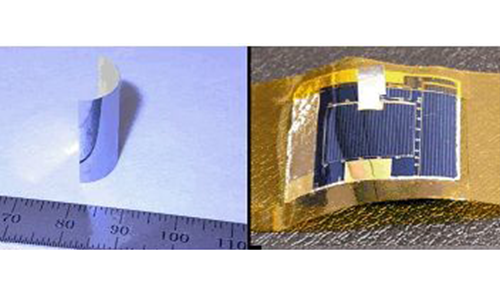

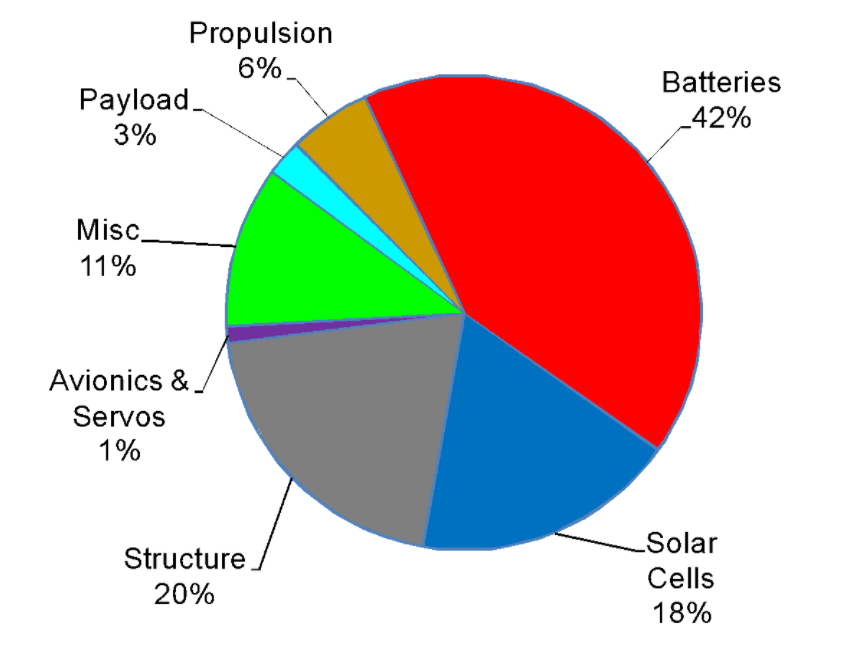

Solar Cell / Rechargeable Battery Technology

| Solar Cell | Type | Power Density (W/ft2) | Areal Density (lb/ft2) | Efficiency (%) |

| Sunpower A300 | Thin Film Cell | 18.6 | 0.143 | 20 |

| Emcore IMM | Thin Film Cell | 30.6 | > 0.1 | ~ 33 |

- Commercially available thin film solar cell efficiencies ~20%

- Will approach 30% in near future

| Battery | Battery Chemistry | Max. Discharge (C) | Voltage (V) | Energy Density |

| Sanyo UR18650F | Lithium-Ion | 2 | 3.7 | 191 W-h/kg |

| Varta PLF 523450 | Lithium Polymer | 2 | 3.7 | 231 W-h/kg |

| SION Power Cell | Lithium-Sulfur | 2 | 3.6 | 350 W-h/kg |

Emcore IMM-3J

Lithium Sulfur Cell

Lithium Polymer Cell

Conceptual Design Trade Study Conclusions

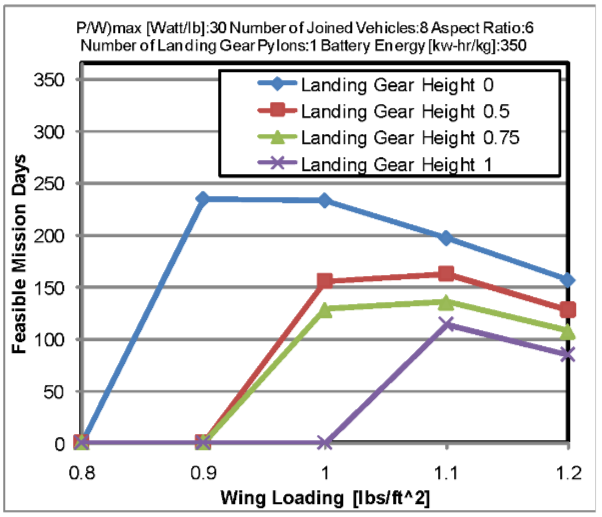

- Minimizing the drag is imperative and retracting or eliminating the landing gear has a significant impact on designs limited by battery energy density

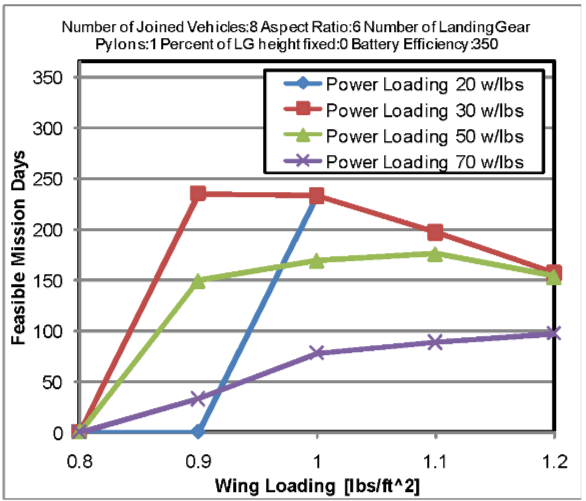

- Select a power loading of 30 W/lbs as there is little difference in the impact of a power loading of either 20 or 30 W/lbs

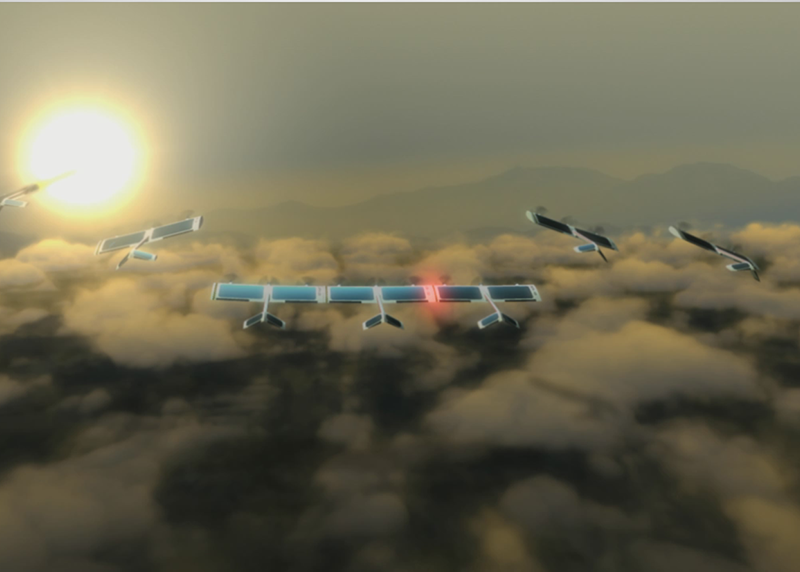

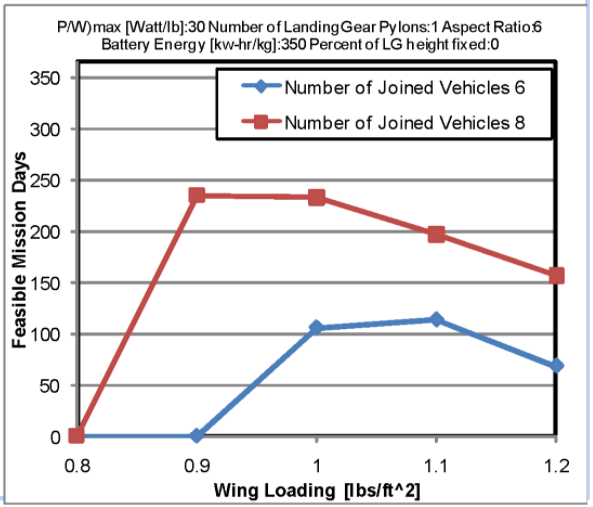

- For the current battery technology 8 linked vehicles offer a significant increase in mission feasible days

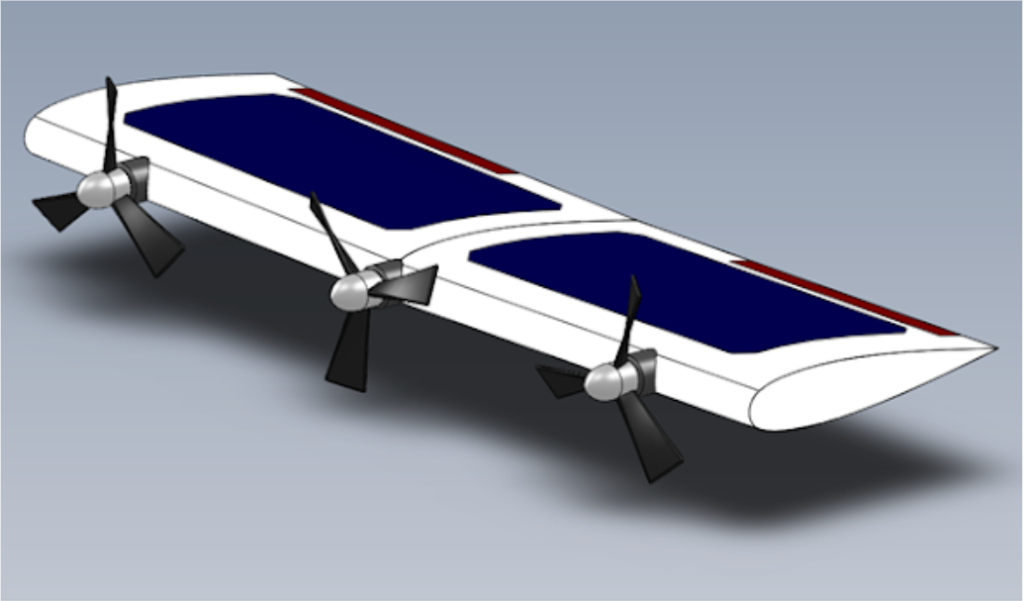

Cellular UAV Conceptual Design

e | 0.8 |

CDo | 0.008 |

W/S | 1 psf |

(P/W)max | 30 W/lb |

AR (cellular) | 5 |

AR (docked) | 40 |

Wingspan (cellular) | 67 ft |

Wingspan (docked) | 536 ft |

W (cellular) | 900 lbs |

W (docked) | 7200 lbs |

Feasible Mission Days | 187 |

CLcruise | 1.17 |

Cellular UAV Conceptual Design

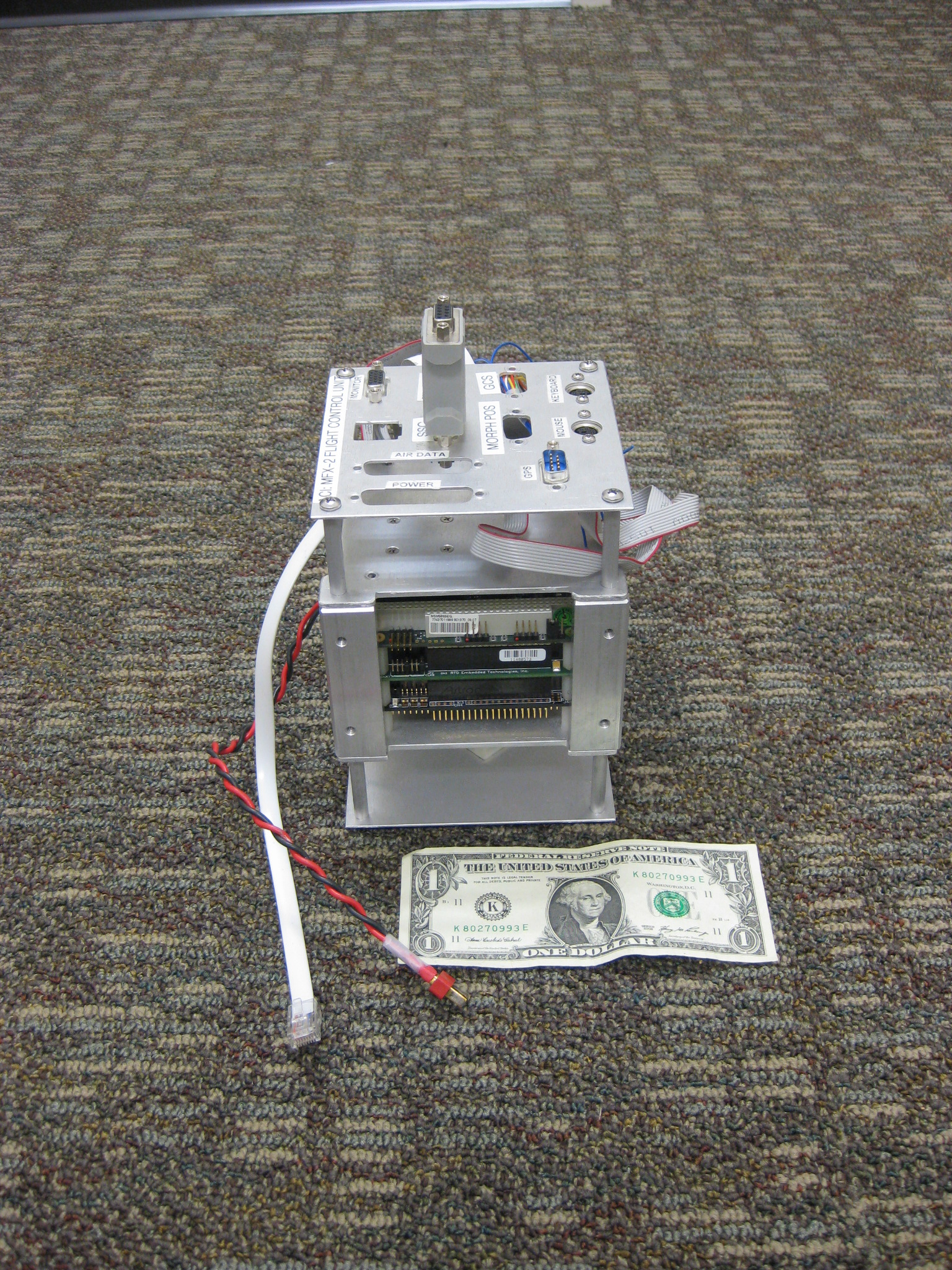

- Developing in-house autopilot for docking demonstration using PC-104 stack

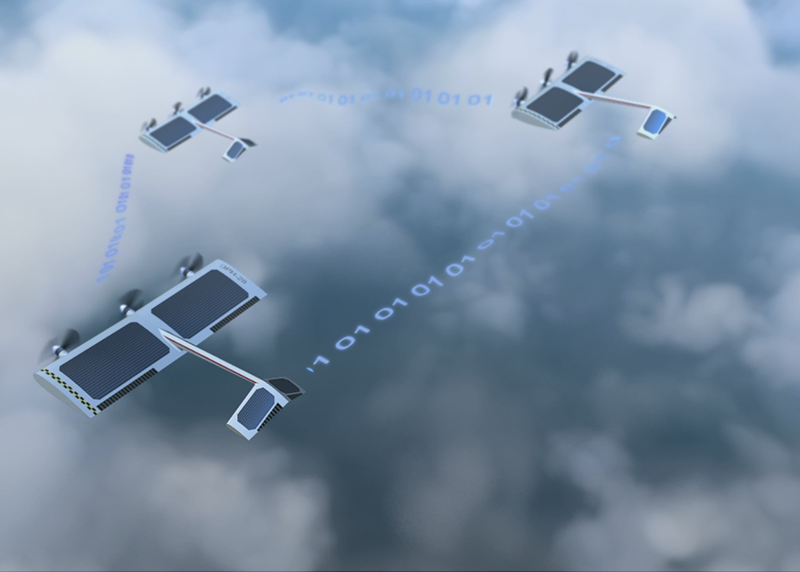

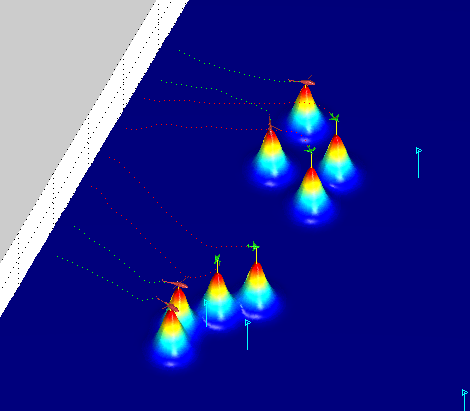

- Simulation of linked vehicle dynamics and control

- High level communication and control for vehicle coordination and threat avoidance

- Optimal trajectory determination for docking when taking close proximity aerodynamics into account

- Simulation of the Cognitive UAV mission in Flight Gear

Risk Mitigation Flight Testing

Evaluate the high risk technologies

- Demonstrate the integration of local proximity sensor technology in a flight environment

- Achieve autonomous close formation flight maneuvers with two vehicles

Reduced risk considerations

- Use proven commercial off-the-shelf components, including the vehicles and autopilot system

- The flight maneuvering, speed, and performance objectives are minimal.

Desired outcome from flight tests

- Computer-controlled flight maneuvers with separations of less than one wingspan using onboard sensor augmentation.

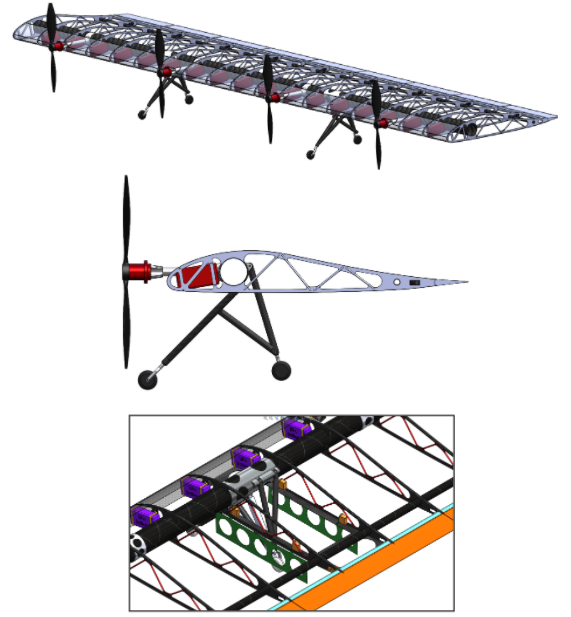

Subscale Vehicle Design

- Based on the conceptual design, the preliminary design of the subscale cellular vehicle was made

- This vehicle will be fabricated in 2011 and flown in 2012.

Parameter | Value |

Aircraft Weight | 185 lbs |

Wing Span | 20 ft |

Wing Root Chord | 3.96 ft |

Wing Tip Chord | 3.96 ft |

AR | 6.19 |

Static Margin | 8 % |

L.E. Spar Diameter | 5 in |

T.E. Spar Diameter | 1.5 in |

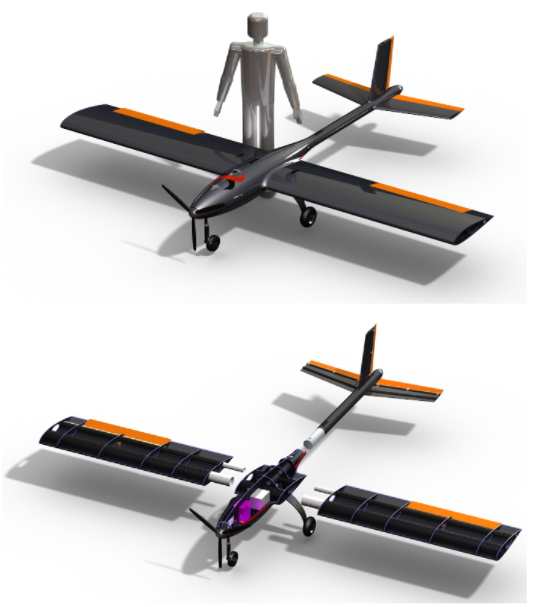

Docking Vehicle Design

- A low cost custom vehicle is being designed and fabricated by NextGen to demonstrate in-flight tip-to-tip docking of UAVs

- This aircraft will be fabricated in 2010 and flight tested in 2010-2011

Parameter | Value |

Aircraft Weight | 120 lbs |

Wing Span | 13.5 ft |

Wing Root Chord | 2.2 ft |

Wing Tip Chord | 2.2ft |

AR | 6.19 |

Aircraft Length | 10.8 ft |

Aircraft Height | 3.6 ft |

Static Margin | 10 % |

L.E. Spar Diameter | 4 in |

T.E. Spar Diameter | 2 in |

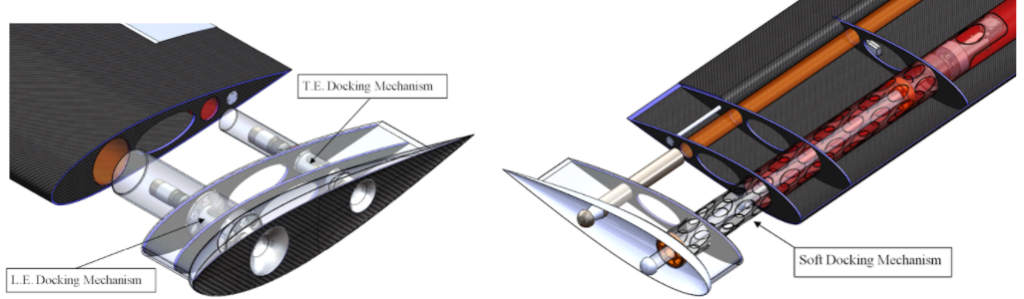

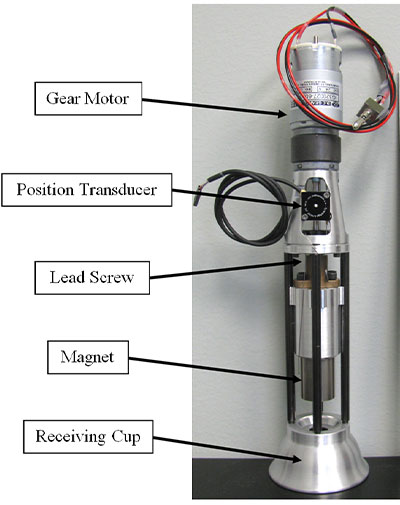

Vehicle Docking Concept

- A ball and socket docking mechanism was selected bas on assessment of possible mechanisms

- A soft docking boom is extended from the aircraft wingtip during flight to the tip of the adjacent aircraft

- A hard dock is then performed at the leading and trailing edges as the soft docking boom retracts

- Three docking mechanism prototypes have been designed and fabricated

- Their performance will be fully characterized with benchtop testing and the final selection will be made

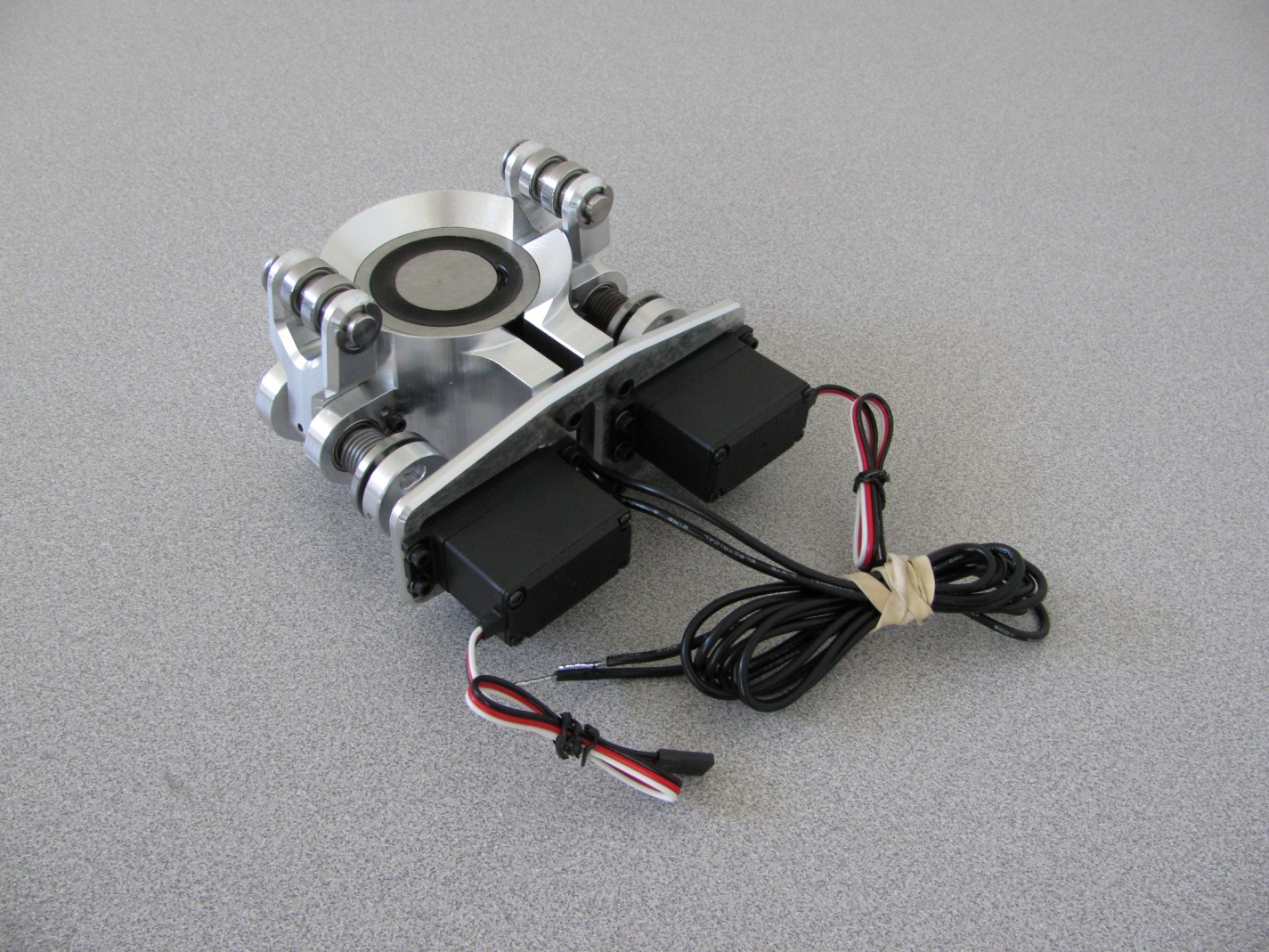

Docking Mechanism Design

Electromagnet / Mechanical Plug Hard Dock

Permanent Magnet (Ball and Socket/Plug) Soft/Hard Dock

Electromagnet (Ball and Socket) Soft/Hard Dock

Progression of Flight Test Vehicles

Vehicles | Size and Uses | |

Sailplanes | Span: Weight: Tests: | 21.5 ft 57 lbs Risk reduction, AP piggyback |

Docking Vehicle | Span: Weight: Tests: | 14 ft 120 lbs Docking demonstration |

Sub-scale Cellular (33%) | Span: Weight: Tests: | 22 ft 187 lbs Subsystems, High/Low level controls |

Full-scale Cellular | Span: Weight: Tests: | 66 ft 900 lbs High altitude, Energy management |

Goals for the Cognitive UAV Program

During the next two years NextGen will demonstrate key technologies in the Cognitive UAV program:

- Be the first to successfully demonstrate autonomous in-flight tip-to-tip docking of the cellular UAVs

- Complete design and manufacture subscale versions of the Cognitive UAV cellular aircraft

- Develop custom in-house cognitive control system capable of coordinating a group of cellular UAVs and docking tip-to-tip in flight